Thursday, June 28, 2018

Tuesday, September 23, 2014

Construction of Wooden Furniture

3:53 AM

The furniture frame should be constructed firmly with joints tightly fitted and glued, corner blocks where needed, and back panel firmly attached. The back panel should be finished for protection but need not be the same finish as the main piece.

Meanwhile, furniture should be safe to use. Test pieces for stability. Be especially alert to cantilevered shapes; tall, thin items; three-legged or pedestal-base tables and chairs; wall system pieces; drawer units in which top drawers might overturn the unit when opened; and furniture on casters.

At last, furniture finishes vary with construction materials and styles. Fine wood furniture and other natural materials often are finished to emphasize their natural beauty. These finishes may be only on the surface or they may penetrate. Because surface finishes stay on the surface of the wood, they easily can be scratched or damaged. Penetrating finishes are absorbed by the wood, durable (if properly applied) and relatively simple to repair if damaged. Finishes protect a surface from soiling and wear.

Http://satriasupply.com.my

Monday, September 22, 2014

Fibreglass Making Process

11:26 PM

Brief Glossary Of Composite Terms

Laminating: Laminating originally referred to applying a thin protective coating of resin and reinforcement over a surface such as wood. The term's use has broadened to include virtually any finished composite part, molded or otherwise. A current example would be: "The part tested was a 10-ply vacuum bagged laminate."

Lamination Schedule: This is a list of the individual layers and orientation of the plies used to construct a composite part, and typically specifies the ounce-weight of the reinforcement and the weave style.

Casting: Casting refers to pouring a large mass of resin into a cavity. The cavity can be a mold when casting parts, or it can be the backside filler for a tool when making the mold itself. It is necessary to use specialized casting resins which generate less heat during their cure and thus create less distortion in the final part. Fibrous fillers can be added as needed to strengthen the casting.

Sculpting: Sculpting is usually accomplished by carving a shape out of polyurethane foam and then laminating the surface. This can be done to create a plug for the molding process, or to shape a finished part in the case of moldless construction.

Reinforcement Types, Properties, and Styles

The physical properties of composites are fiber dominant. This

means that when resin and fiber are combined, their performance remains

most like the individual fiber properties. For example, it is not

satisfactory to merely average the tensile strengths of fabric and

resin to determine the strength of a panel. Test data shows that the

fibrous reinforcement is the component carrying the majority of the

load. For this reason, fabric selection is critical when designing

composite structures. Fabricators today choose from three common

reinforcements, including fiberglass, carbon fiber, and Kevlar®. Each comes in various forms and styles, and has benefits and drawbacks that should be analyzed before starting any project.Thursday, May 5, 2011

Your Restaurant Expertise.

5:56 AM

INTRODUCTION

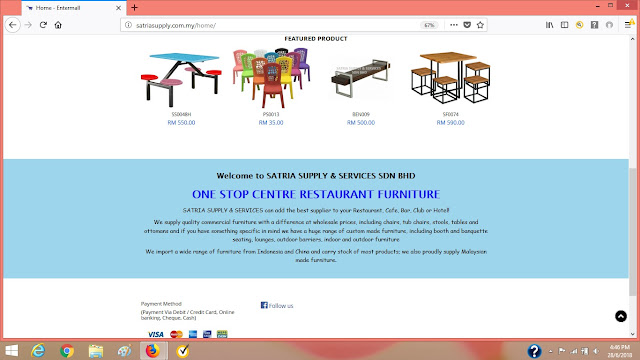

SATRIA SUPPLY & SERVICES can add the best supplier to your Restaurant, Cafe, Bar, Club or Hotel!

We supply quality commercial furniture with a difference at wholesale prices, including chairs, tub chairs, stools, tables and ottomans and if you have something specific in mind we have a huge range of custom made furniture, including booth and banquette seating, lounges, outdoor barriers, indoor and outdoor furniture.

We understand and appreciate the many challenges of contractors face regarding accuracy, complexity and deadline. We will support those contractors and their deadlines to the best of our ability. Not only with the common off the shelf items, but also diverse and custom items made especially for your particular project.

Our Interior Designer can help you through your design process – from initial concept of selecting furniture pieces, colours and textures, to quotation, right through to installation. Just bring in your floor plans and Asfiza can customise a design that is prefect for you and your venue to make you stand out in the market!

We import a wide range of furniture from Indonesia and China and carry stock of most products; we also proudly supply Malaysian made furniture.

We can deliver to Peninsular Malaysia, Sabah, Sarawak, Brunei, Asian and European countries.

Services Information.

Please call +6019-7500091 for further information.

Open

9.00am - 6.00pm (Monday - Friday)

9.00am - 1.00pm (Saturday)

Close on Sunday and Public Holiday

We supply quality commercial furniture with a difference at wholesale prices, including chairs, tub chairs, stools, tables and ottomans and if you have something specific in mind we have a huge range of custom made furniture, including booth and banquette seating, lounges, outdoor barriers, indoor and outdoor furniture.

We understand and appreciate the many challenges of contractors face regarding accuracy, complexity and deadline. We will support those contractors and their deadlines to the best of our ability. Not only with the common off the shelf items, but also diverse and custom items made especially for your particular project.

Our Interior Designer can help you through your design process – from initial concept of selecting furniture pieces, colours and textures, to quotation, right through to installation. Just bring in your floor plans and Asfiza can customise a design that is prefect for you and your venue to make you stand out in the market!

We import a wide range of furniture from Indonesia and China and carry stock of most products; we also proudly supply Malaysian made furniture.

We can deliver to Peninsular Malaysia, Sabah, Sarawak, Brunei, Asian and European countries.

Services Information.

Please call +6019-7500091 for further information.

Open

9.00am - 6.00pm (Monday - Friday)

9.00am - 1.00pm (Saturday)

Close on Sunday and Public Holiday

SATRIA SUPPLY & SERVICES SDN BHD

(1080147-A)

(1080147-A)

N0.10, Jalan Besi 1/2, Lebuhraya LEKAS 32,

Kawasan Perindustrian Sg,Purun,

43500 Semenyih, Selangor Darul Ehsan.

Kawasan Perindustrian Sg,Purun,

43500 Semenyih, Selangor Darul Ehsan.

satriasupply@gmail.com

Central Business Information Limited (CBI) is a global business information company covering Hong Kong, China and 140 countries around the world.

Registered With MOF

Registration No : 357-02174927

Code registered : 020010 (furniture)